As the demand for plastic welding continues to rise in various industries, it is essential to emphasize the importance of quality and efficiency in the welding process. Handheld extruders or extrusion welders play a crucial role in achieving precise and durable plastic welds, making them indispensable tools for professionals in the field.

Handheld extruders are versatile tools that are used to extrude and weld thermoplastic materials. They are designed to be lightweight and easy to maneuver, allowing for greater precision and control during the welding process. With the ability to extrude plastic materials directly onto the welding surface, handheld extruders enable welders to create strong and seamless bonds between plastic components.

Extrusion welders are powerful machines that are capable of producing high-quality welds in a wide range of plastic materials. These welders utilize a continuous plastic welding rod, which is heated and extruded onto the joint, creating a strong and reliable bond. With advanced features such as temperature control and adjustable extrusion speed, extrusion welders offer welders the ability to tailor the welding process to the specific requirements of each project.

In industries such as construction, automotive, and manufacturing, the demand for high-quality plastic welding continues to grow. As a result, the reliance on handheld extruders and extrusion welders has become increasingly prevalent. These tools not only enable welders to produce strong and reliable welds but also contribute to the overall efficiency and cost-effectiveness of the welding process.

The advancements in handheld extruder and extrusion welder technology have led to the development of more ergonomic and user-friendly designs. This has made these tools more accessible to a wider range of professionals, allowing for greater innovation and creativity in plastic welding applications.

The role of handheld extruders and extrusion welders in plastic welding cannot be overstated. As the demand for high-quality plastic welds continues to rise, these tools have become essential for achieving precise, durable, and efficient welds in various industries. By investing in quality handheld extruders and extrusion welders, professionals can ensure the integrity and longevity of their plastic welds, ultimately contributing to the success of their projects.

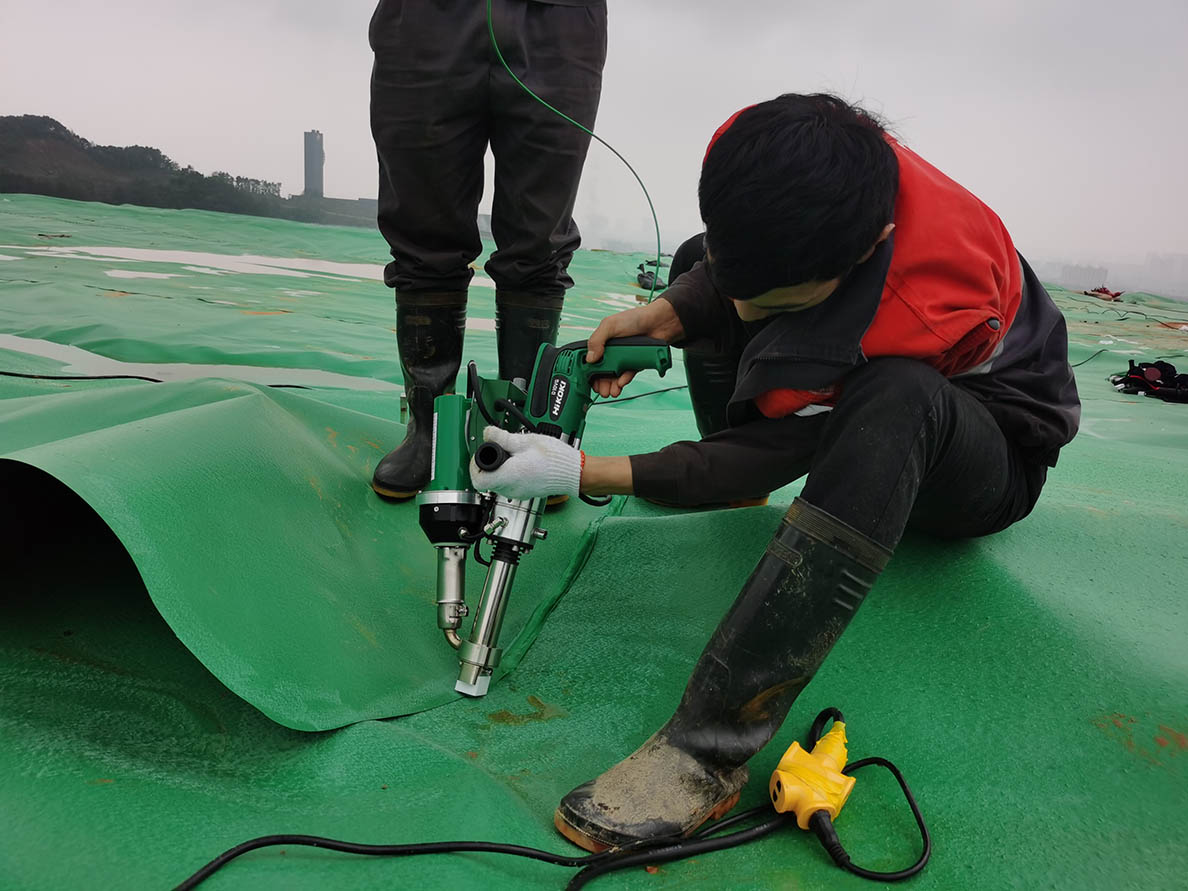

Plastic Hand Extrusion LST600A

The extrusion welding gun is the first in China to provide functions such as dual independent heating of base material and welding rod, digital temperature control display, 360-degree rotating welding nozzle, and motor cold start protection. Using Japanese Hikoki electric drill as the extrusion motor, the machine is small and exquisite, the operation is convenient, the performance is stable, and it can be continuously welded. It is suitable for the welding of PE, PP plastics.

Post time: Mar-15-2024