Operation Manual LST Floor

Application

LST-FLOOR is intended for professional use for laying elastic floor coverings

Precautions

Unplug the tools before opening it to avoid of being hurt by exposed wires or component inside the machine with power.

Incorrect use of it can cause fire and explosion hazard because of high temperature, especially near combustible materials and explosive gases.

Don’t touch heater tube and nozzle when they are hot. They may cause burns. Don’t point hot air flow in the direction of people or animals.

The voltage rating stated on the welder must correspond to line/mains voltage (220V). The drop cable / wire with protective earthed conductors can only be used.

To ensure operator safety and reliable operation of equipment, the power supply must be installed power supply and leakage protection at the construction site.

It must be running at the correct use of manipulation of the operator, or they may cause a fire or explosion caused by high temperature.

Don’t use welder in the water, or on a muddy construction site, to avoid flooding, rain or moisture.

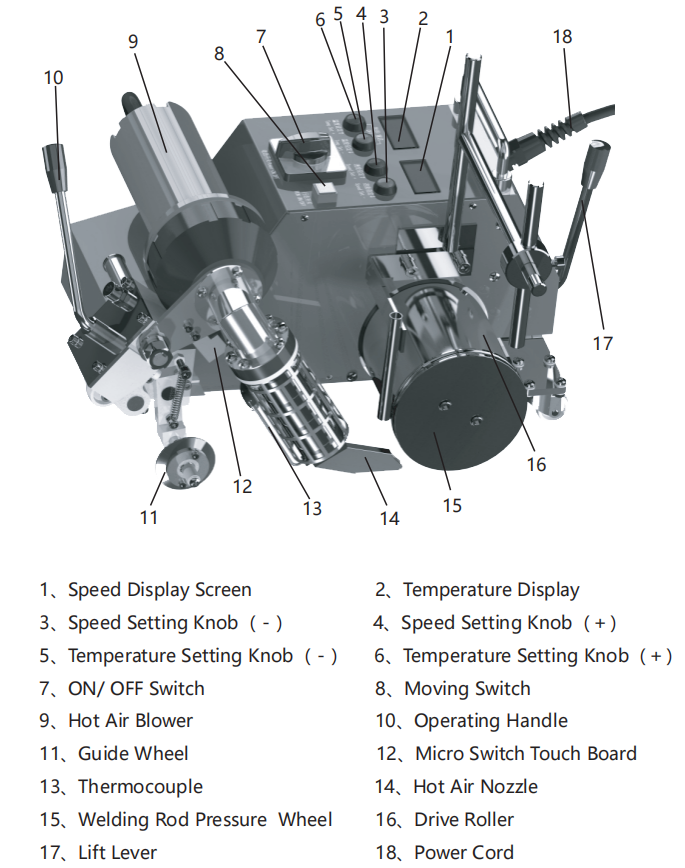

Main Parts

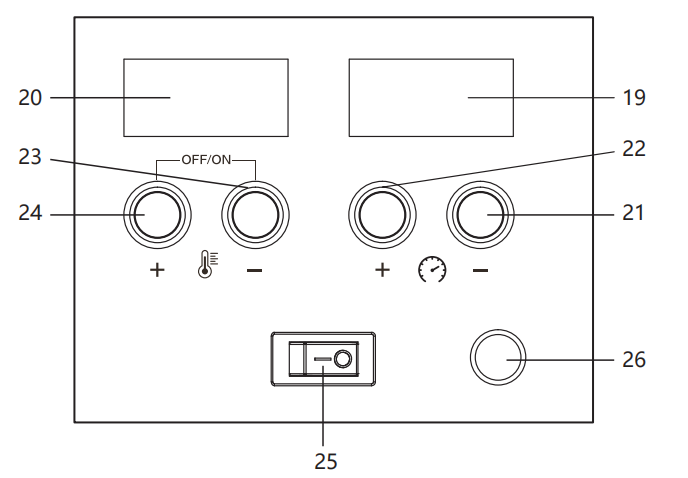

Control Panel

1、ON/OFF switch(25)is used for open the main power of the welder.

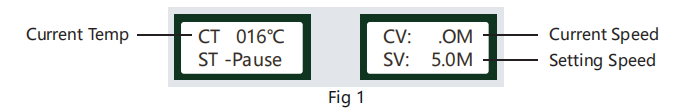

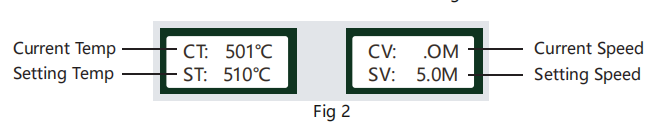

2、Open ON/OFF switch (25), LCD display is shown as figure 1,the hot air blower is under natural wind without heating.

3、Press the button (23) and(24), the screen shows as Figure 2 and the hot air blower starts to heat until to the setting temperature.

4、If press the bottoms (23) and (24) at the same time, LCD display shows as figure 1, the hot air blower is under natural wind without heating.

5、When the welding nozzle is at the right position, press the moving switch (26) and the welder starts to move and weld. It will stop move if you press the moving switch again.

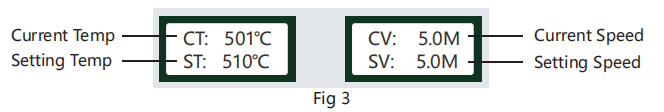

6、When the welder starts to move, the LCD display shows as figure 3.

Parameters Setting

Parameter

|

Model

|

LST-FLOOR

|

|

Voltage

|

230 / 120 V

|

|

Frequency

|

50 Hz

|

|

power

|

2600 / 2000 W

|

|

Temperature

|

0~550 ℃

|

|

Welding Speed

|

1.5 - 10.0 m/min

|

|

Welding width

|

20 / 30 mm

|

|

Size( L*W*H)

|

475 * 290 * 205 mm

|

|

Weight

|

12.5 kg

|

Welding Parameters Setting

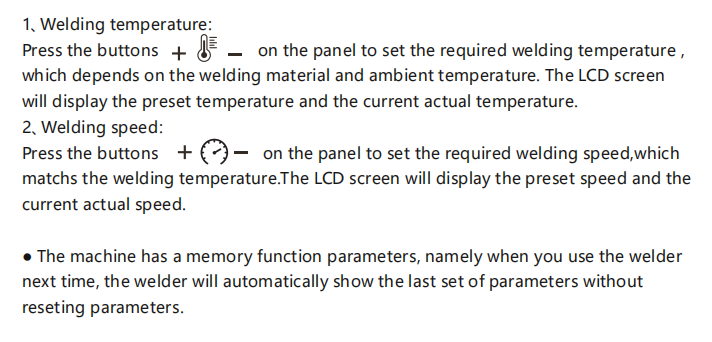

1、Rolling in welding rod as figure 4.

2、Setting welding parameters.

3、Please wait the actual temperature value reaching the setting value.

4、Positioning the welder to move Guide wheel (11) and welding rod pressure wheel (15) in the middle of welding groove.

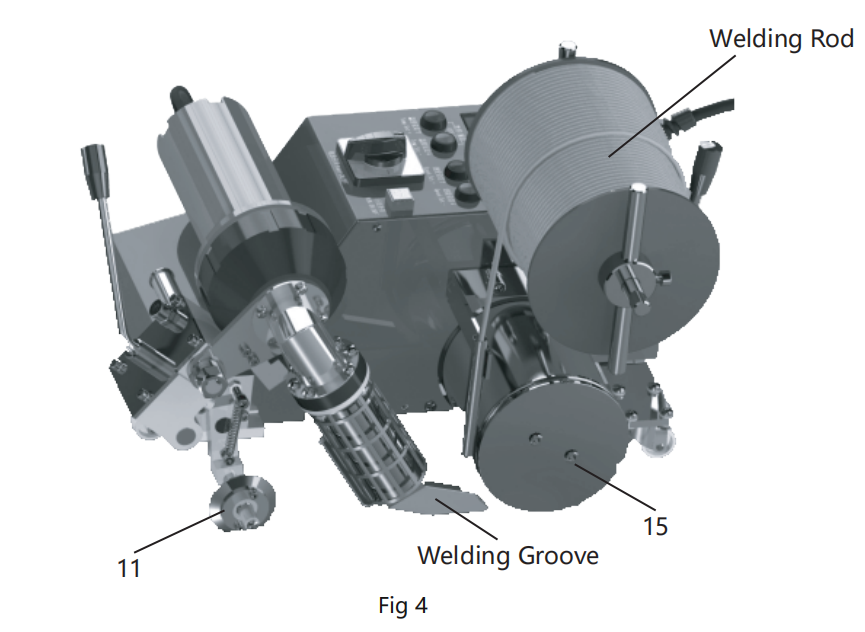

5、Feeding in welding rod as figure 5.

6、Lift the Lift leve(17)to up Universal wheel from floor and put the welding rod preesure roller(15)on welding rod.

7、Push ahead Guide wheel drive set to press Guide wheel (11) on welding groove and support the machine.

8、Lift Operating handle(10), lower down hot air welding nozzle(14)to close the floor,counterclockwise Operating handle(10)to put hot air welding nozzle in the middle of welding rod and welding groove, then the machine would start walking and welding automatically.

9、To observe the relative positions of Guide wheel(11).and welding rod pressure wheel (15).

10、When the welder walks into the end of material, clockwise the operating handle (10) to pull the hot air nozzle to right side. Then pressure the operating handle (10) to lift the hot air nozzle.

11、After finish the welding job, press the Temperature setting knob+ and Temperature setting knob- to make the hot air blower in a cold blowing condition in order to cool the nozzle.

12、Last step is to off power.

Welding Parameters Setting

Welding Parameters Setting

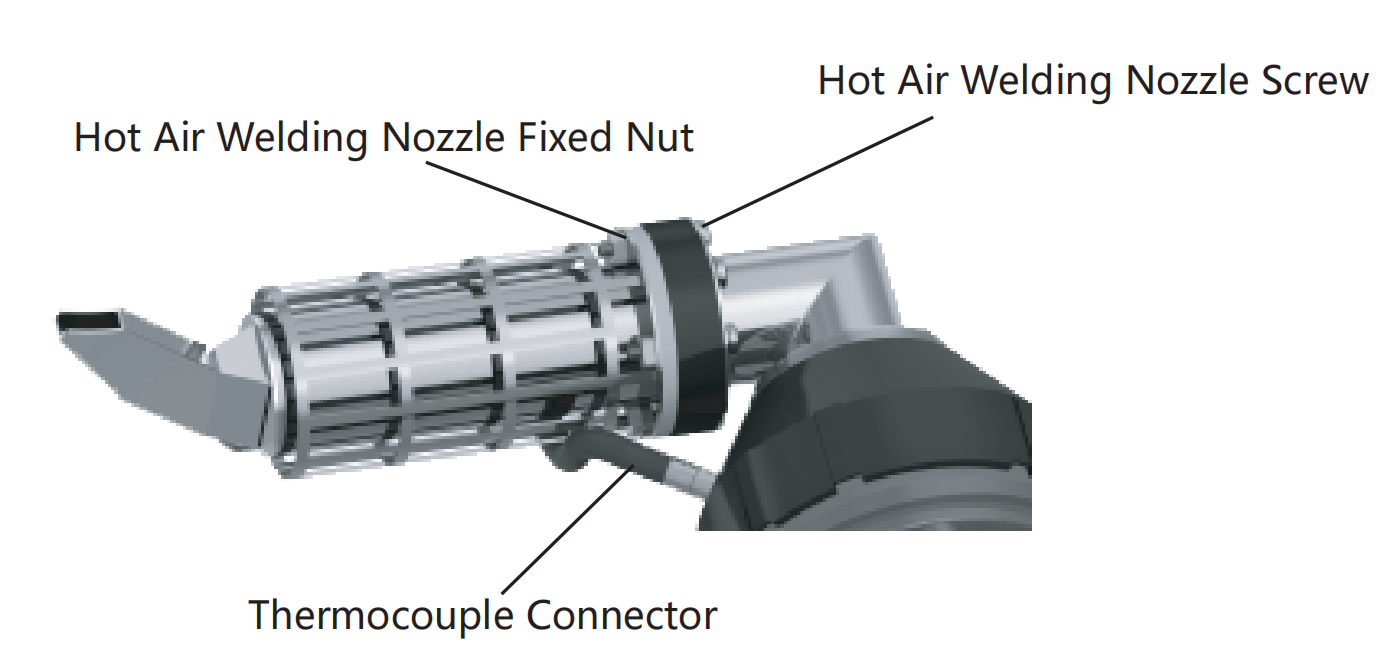

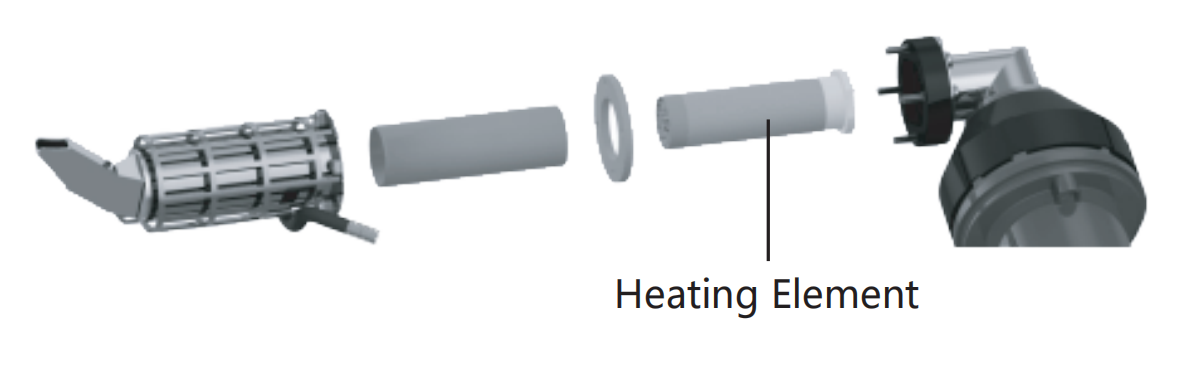

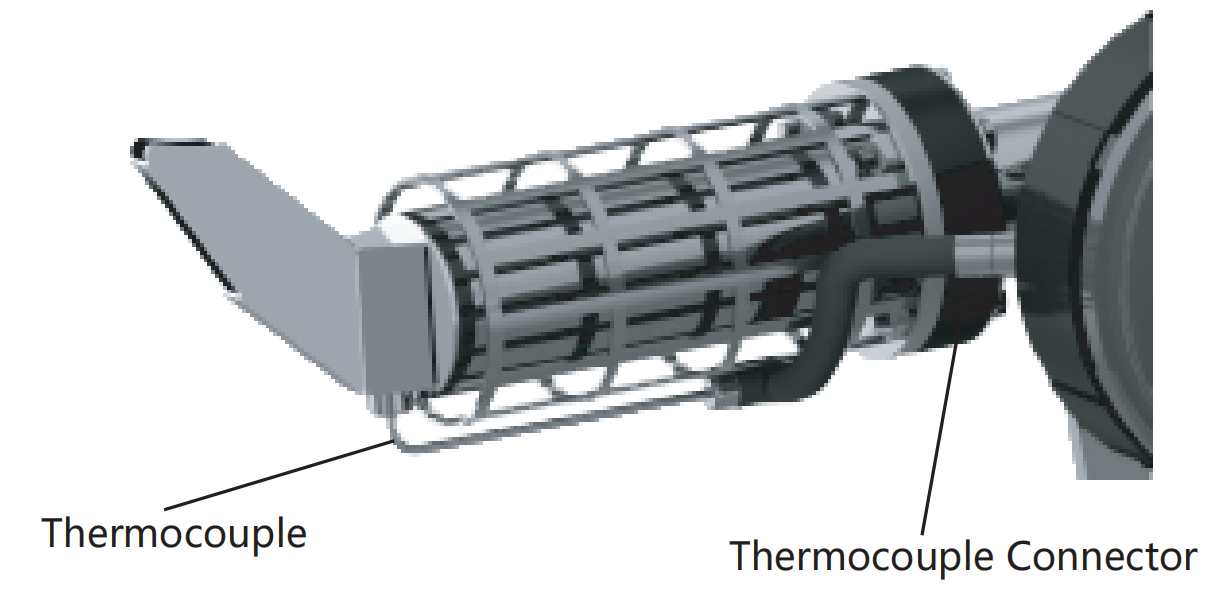

1、Replacement of heating element

Unplug the thermocouple connector,Loosen the fixing screws and nuts of nozzle. Then you can remove the heating element after removing the nozzle.

As shown on the right:

Quality Assurance

· This product guarantees a 12-month shelf life from the day it is sold to consumers. We will be responsible for failures caused by material or manufacturing defects. We will repair or replace defective parts at our sole discretion to meet the warranty

requirements.

· The quality assurance does not include damage to wearing parts (heating elements, carbon brushes, bearings, etc.), damage or defects caused by improper handling or maintenance, and damage caused by falling products. Irregular use and unauthorized modification should not be covered by the warranty.

Standards

The company declares that the products manufactured and marketed by the company meet the requirements of the following enterprise implementation standards.

Standards:Q/3500100LST 001.

Repairs and Spare Parts

· It is strongly recommended to send the product to Lesite company or authorized repair center for professional inspection and repair.

· Only original Lesite spare parts are allowed.

Write your message here and send it to us