Operation Manual LST-MAT1 MAT2

Application

(1) Splicing and production of advertising printing

(2) car tents

(3) membrane structures

(4) automobile transportation

(5) inflatable castles

(6) tents

(7) open-air storage

(8)plastic

Precautions

Parameter

Please confirm that the machine is turned off and unplugged

before disassembling the welding machine so as not to be

injured by live wires or components inside the machine.

The welding machine generates high temperature and high

heat, which may cause fire or explosion when used incorrectly,

especially when it is close to combustible materials or explosive gas.

Please do not touch the air duct and nozzle(during welding work or

when the welding machine has not completely cooled down),

and do not face the nozzle to avoid burns.

The power supply voltage must match the rated voltage

marked on the welding machine and be reliably grounded. Connect

the welding machine to a socket with a protective ground conductor.

In order to ensure the safety of the operators and the reliable

operation of the equipment, the power supply at the construction site

must be equipped with a regulated power supply and a leakage protector.

The welding machine must be operated under the correct control of the

operator, otherwise it may cause combustion or explosion due to

high temperature.

It is strictly forbidden to use the welding machine in water or muddy

ground, avoid soaking, rain or damp.

| Model | LST-MAT1 |

| Rated Voltage | 230 V |

| Frequency | 50 / 60 Hz |

| Rated Power | 4200 W |

| Welding Speed |

1.0 - 10.0 m/min |

| Heating Temperature | 50 - 620 ℃ |

| Seam Width | 40 / 50 / 80 mm |

| Net Weight | 22.0 Kg |

| Motor | Brush |

| Certificate | CE |

| Warranty | One year |

| Model | LST-MAT2 |

| Rated Voltage | 230 V |

| Frequency | 50 / 60 Hz |

| Rated Power | 4200 W |

| Welding Speed |

1.0 - 10.0 m/min |

| Heating Temperature | 50 - 620 ℃ |

| Seam Width | 40 / 50 / 80 mm |

| Net Weight | 22.0 Kg |

| Motor | Brush |

| Certificate | CE |

| Warranty | One year |

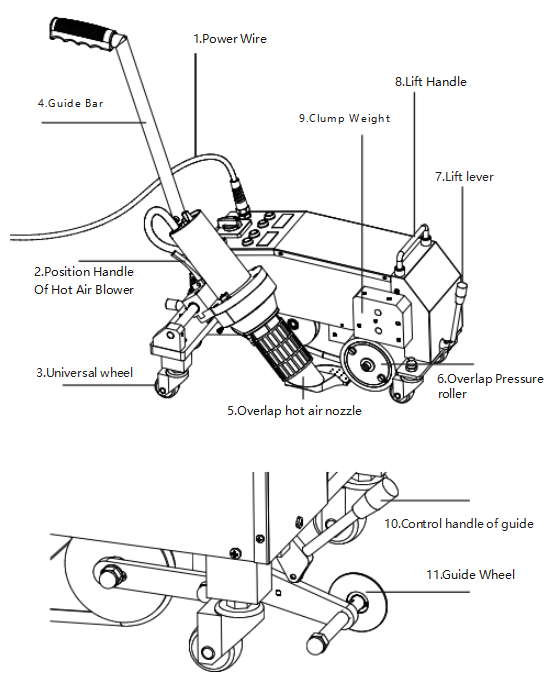

LST-MAT1 Main Parts

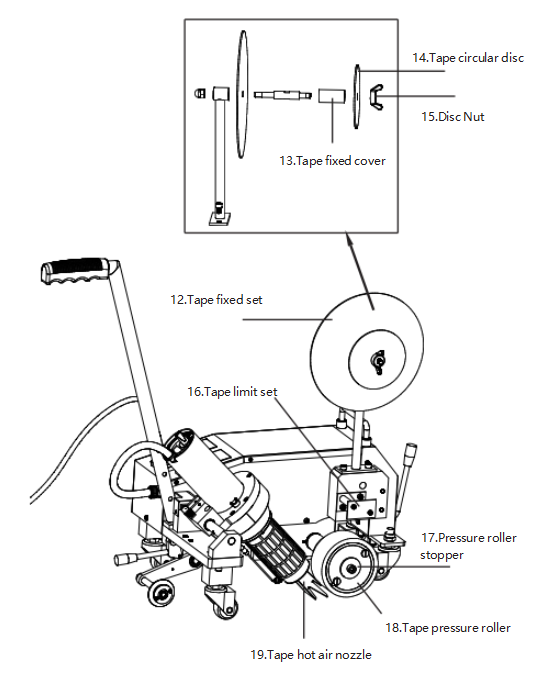

LST-MAT2 Main Parts

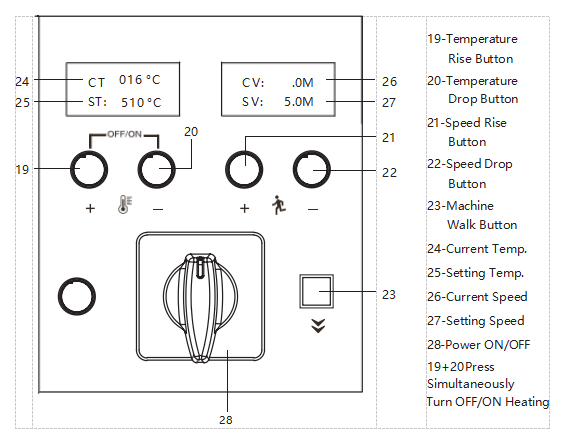

Control Panel

1.Welding temperature:

Using bottoms to set the required temperature. You can set the temperature according to the welding materials and the ambient temperature. LCD display screen will show the setting temperature and the current temperature.

to set the required temperature. You can set the temperature according to the welding materials and the ambient temperature. LCD display screen will show the setting temperature and the current temperature.

2. Welding speed:

Using bottoms  to set the required speed according to the welding temperature.

to set the required speed according to the welding temperature.

LCD display will show the setting speed and the current speed.

● The machine has a memory function parameters, namely when you use the welder next time, the welder will automatically use the last setting parameters without having to

re-set parameters.

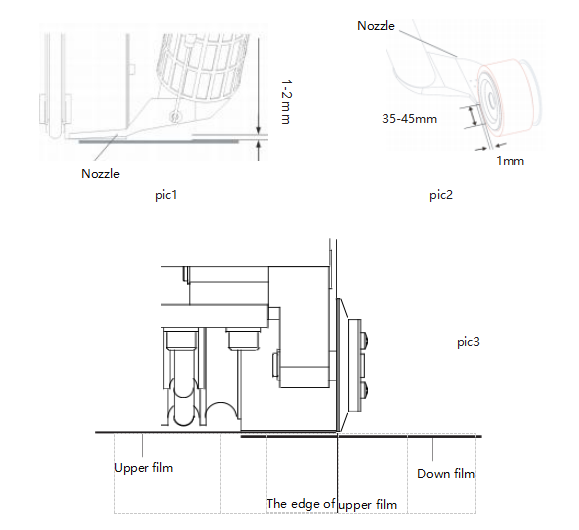

Welding Nozzle Setting

1. The distance between the air nozzle and the ground should be shown in pic1 (the distance has been adjusted before delivery).

2. The distance between the air nozzle and the pressure wheel should be as shown in pic2 and pic3 (the distance has been adjusted before delivery). If the distance is not correct, loosen the fixing screws below the air gun fixing base (left)(14) and the air gun fixing base (right)(15) for adjustment.

3. The tape welding should be installed as shown in pic3.

Boot/Shutdown Steps

① Turn on the machine, and the LCD display screens are shown as above. At this time, the air blower does not heat and is in the state of blowing natural wind.

② Press the buttons Temperature Rise (14) and Temperature Drop (15) at the same time. At this time, the air blower starts to heat up to the setting temperature. When the current temperature reach the setting temperature, press button Speed Rise(16) to set speed. The LCD screens are shown as above.

③ Pull up the Blower Location Handle, raise the Hot Air Blower , lower the Welding Nozzle to make it close to the lower membrane, move the air blower to the left to insert the welding nozzle into the membranes and make the welding nozzle in place, At this time, the welding machine automatically walks for welding. The LCD screens are shown above.

④ Pay attention to the position of the Guide Wheel at all times. If the position deviates, you can touch the Operating Handle to adjust.

⑤ After completing the welding work, remove the welding nozzle and return to the initial position, and press the buttons Temperature Rise and Temperature

Drop on the control panel at the same time to turn off the heating. At this time, the hot air blower stops heating and is in cold air standby mode while allowing the welding nozzle to cool down after waiting for the temperature to drop to 60°C, and then turn off the power switch.

Error Code

| Error Code | Description | Measures |

| “Error T002” | No thermocoupledetected | a.Check thermocouple connection b.Replace thermocouple |

| “Error S002” | No heating element detected | a.Check heating element connection b.Replace heating element |

| “CT:999 Err-T001” | Thermocouple failure in operation | a.Check thermocouple connection b.Replace thermocouple |

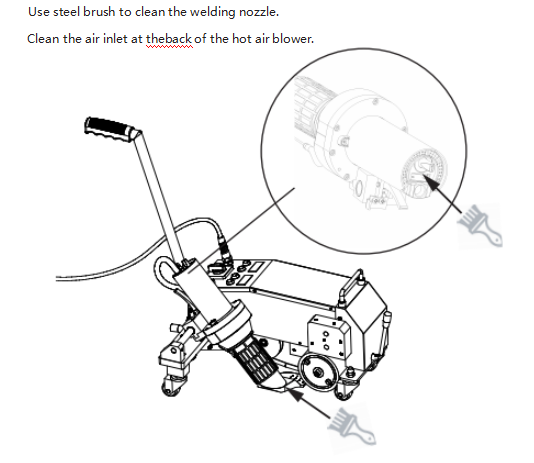

| “Error FANerr” | Overheating | a.Check hot air blowerb.Clean nozzle and filter |

Nameplate

Daily Maintenance

Quality Assurance

· This product guarantees a 12-month shelf life from the day it is sold to consumers. We will be responsible for failures caused by material or manufacturing defects. We will repair or replace defective parts at our sole discretion to meet the warranty requirements.

· The quality assurance does not include damage to wearing parts (heating elements, carbon brushes, bearings, etc.), damage or defects caused by improper handling or maintenance, and damage caused by falling products. Irregular use and unauthorized modification should not be covered by the warranty.

Maintenance

· It is strongly recommended to send the product to Lesite company or authorized repair center for professional inspection and repair.

· Only original Lesite spare parts are allowed.